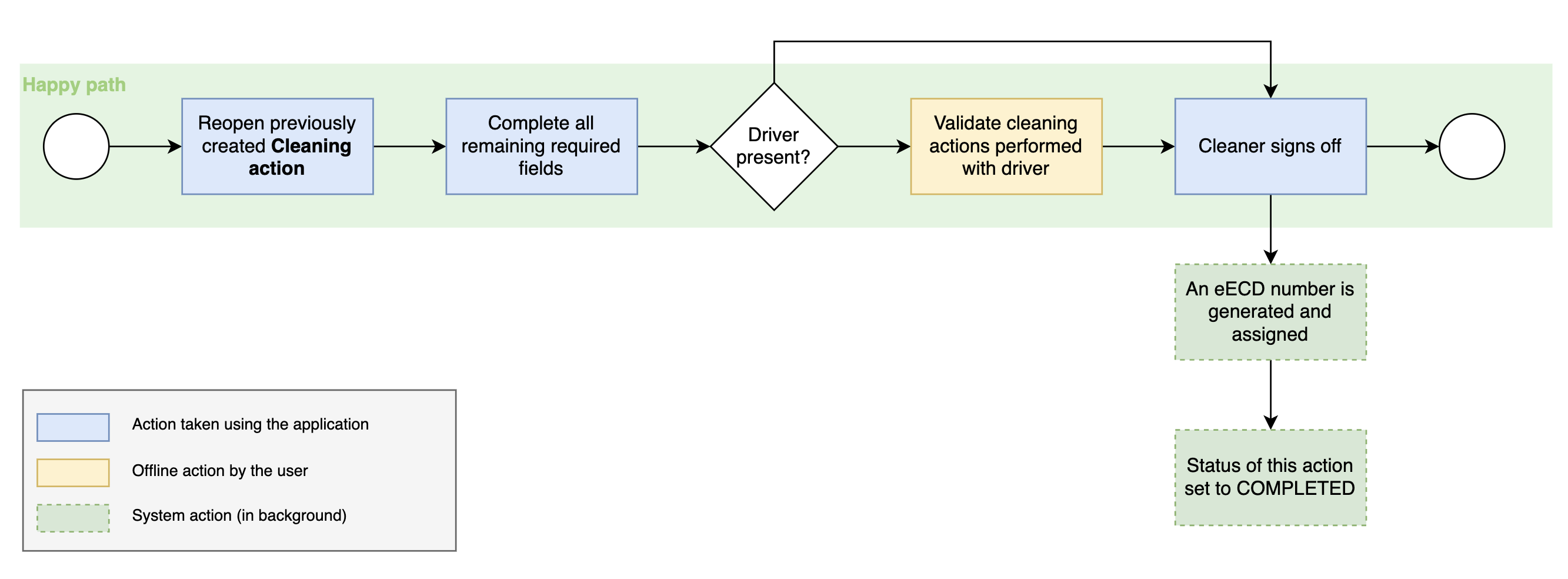

Perform Cleaning

Start: see Validate Cleaning Request (assuming the CleaningOperator does not perform these steps immediately after step A, which results in an opened booklet (and a created cleaning action) for equipment E, or after login of the operator.

In both cases, the user login identifies ECD.Field1: cleaning location

Cleaner name and location’s address are prefilled based upon login credentials, if the user is linked to a cleaning location

If the user is not linked, a dropdown of all cleaning locations for the user’s Cleaner organization is shown

Action | Comment |

(Re)open the previously created new cleaning page in the booklet. The eECD status is “planned” and remaining fields can be completed | Support/attach additional documents to cleaning action (such as pressure test certificates) needs to be supported |

Fields to complete:

Underlined fields are automatically generated as they are known.

1. company details of the cleaning station

these data are derived from user parameters (from login and/or from step A), see master data description

cleaningCompanyName: organisation.name

cleaningAddress: location.address

cleaningPhone: location.phone

cleaningFax: location.fax

cleaningWebsite: organization.website

2. cleaningPoReference

provided by EquipmentOperator, entered manually (optionally)

3. cleaningInternalReference

unique reference to the administrative system of the cleaning station so the eECD order can be linked to the cleaning order

4. equipment operator

5. equipment details

as the booklet is open at this point, we know which equipment we are talking about. As a result, these fields do not have to be entered

6. cleaningProductNature

would be driven by previous load for compartments that are being cleaned

from product master data, field productType (typically chemical in this project)[1]

7. previous load / compartment

compartmentNumber: identifier for the tank compartment (number)

UNNr: UN number -- only needed in case of dangerous goods (derived from the SDS and/or copied from the CMR)

productName: last loaded product

The previous cargo is already registered per compartment. Per compartment the chemical name, trade name or proper shipping name has to be entered

8. cleaning actions

cleaningEftcoCodes: Text field that contains the EFTCO codes per compartment

Per compartment the codes have to be entered by the cleaning station. Keep in mind that a single EFTCO code can be used multiple times per compartmentEFTCO cleaning code master data (code list) is to be defined/maintained on the platform. Structure available on EFTCO website in multiple languages[2].

9. additional services

Additional services are mentioned in this box and can be entered per compartment, but also for the complete equipment

10. comments

11. cleaning operator name: optional (text field)

cleaningCleanerName: field contains the name of the operator who performed the cleaning, to be entered manually

12. timestamps

cleaningStartDate: TIME IN DateTime field that represent the start of the cleaning of the equipment at the cleaning station (Optional)

cleaningEndDate: TIME OUT vDateTime field that represent the end of the cleaning operation and correspondents with the date/time the equipment leaves the cleaning bay (Mandatory).

This allows a notification to be sent to EquipmentOperator when cleaning is done

If the driver is not present, the performed cleaning actions and comments are verified by the Cleaner and can be signed off on behalf of the driver. This is called an unaccompanied cleaning and is defined as part of the cleaning request. | unaccompanied cleaning = cleaning where the equiment is put on depot after cleaning and is picked up after working hours. A pdf copy can be used as guidance in the container document holder |

Confirm cleaning has been done correctly (close the cleaning action)

| The EECD numbering is as follows: “EECD” followed by a 12-digit number so you get the following sequence: EECD xxxx xxxx xxxx |

At this point, the cleaning action is visible to the EquipmentOperator. It is not yet visible for anyone else as the cleaning has not been signed off by the EquipmentOperator until step C | Cleaning action or eECD status is now ‘completed'. The content of the cleaner fields are frozen. |

POLYMER Cleaning

Before starting the cleaning, the cleaner can select the cleaning option “polymer cleaning” via a tickbox; In this case, the eECD being issued is checked automatically against all the minimum required EFTCO codes which are part of the Polymer cleaning best practice guideline as put together by Cefic-ECTA-EFTCO assoications. This check happens at the moment of eECD saving and eECD cleaner signoff.

Recleaning

It can happen that an equipment needs to be re-cleaned or a previously cleaned tank needs additional cleaning actions (and assuming no load was done in the meantime). In such case the follwoing needs to happen:

When an extra rinsing is performed at the same cleaning station, on the same equipment compartment and the previous ECD or eECD is still valid

a new eECD is issued with reference to the former eECD

this new eECD makes reference to the previous cleaning eECD in the booklet via the eECD comment box (=box11 on EFTCO cleaning document)

if there are additional actions necessary to respect the requirements of the next loading place which were not known when the first cleaning was done

these extra actions will be indicated on the new eECD

the EFTCO codes of the “old” ECD are taken over to new one ECD together with a comment on the new eECD

the code T01 and/or the new codes of the additional cleaning actions which were done need to be added by the cleaning operator

if the paper process was used, the former paper ECD needs to be scanned and attached to the cleaning action. It is the task of the cleaning administrator to add the evidence (= upload the previous ECD paper evidence and mention that in the comments box 11 on the eECD (comments)

the operator needs to indicate all relevant EFTCO codes

When an extra rinsing is performed at another cleaning station on the same equipment compartment and the previous ECD is still valid

a complete new eECD is issued and the normal eECD cleaning process applies

The new eECD invalidates the previous eECD (as always), so there is only one valid eECD per compartment at any time.